Easy, Illustrated Instructions on How to Fix a Fog Machine

Fog machines are pretty straightforward. They vaporize fluid into a mist, or maybe they atomize it.

Liquid goes in, mist comes out.

Small home and hobby fog machines are engineered to work in cycles, making fog on and off for a few minutes at a time. I believe this allows the heater to maintain the optimal fog-producing temperature.

Fog machines use sticky fluid which flows easily with regular use but dries into gum when it is left to sit in the non-halloween months. The symptoms of a gummed-up fog machine are a machine that turns on, lights up, warms up and hums, but does not produce fog vapor.

The blockage is probably at the pump. To clear it, push water through the tube. Below is a description of how the parts of a fogger work together, including detailed instructions on how to remove these inevitable blockages.

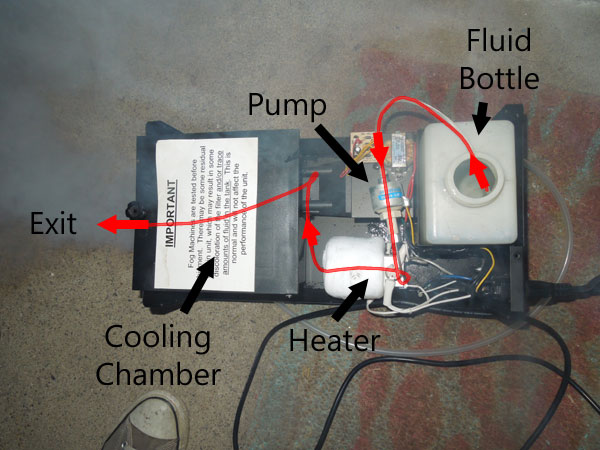

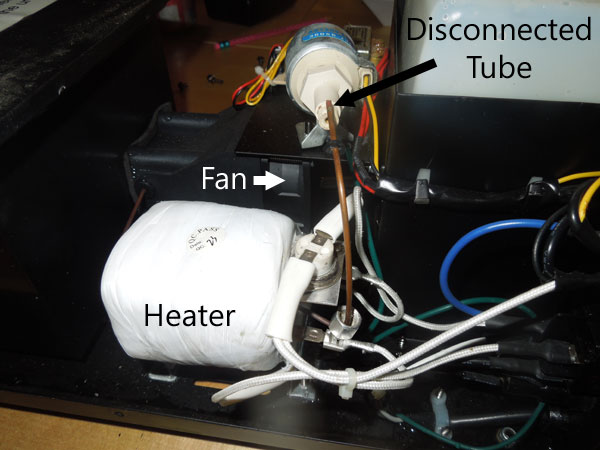

The fog machine has four elements, a bottle, a pump, a heater and (probably) a cooler.

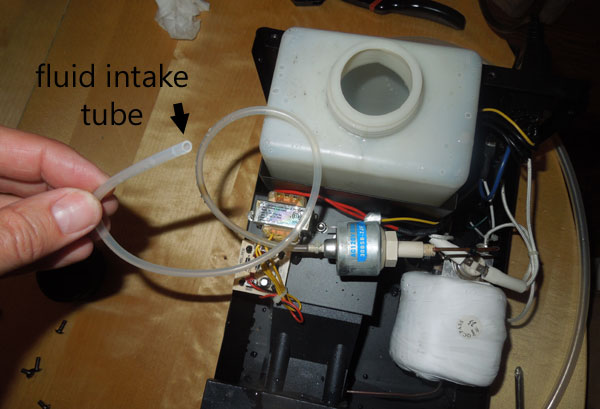

A thin rubber tube rests within the fog fluid bottle and should provide a path to the heater. The pump is round and looks a bit like a spool of thread. I believe this is a peristaltic pump, designed to pump thick liquids (like blood) in a very controlled manner. This type of pump is particularly good at keeping clear, but with very small tubes sometimes clogs happen.

Before the pump, the fluid travels through a rubber tube, after the pump, the fluid uses a metal tube, about a big around as a coffee stirrer.

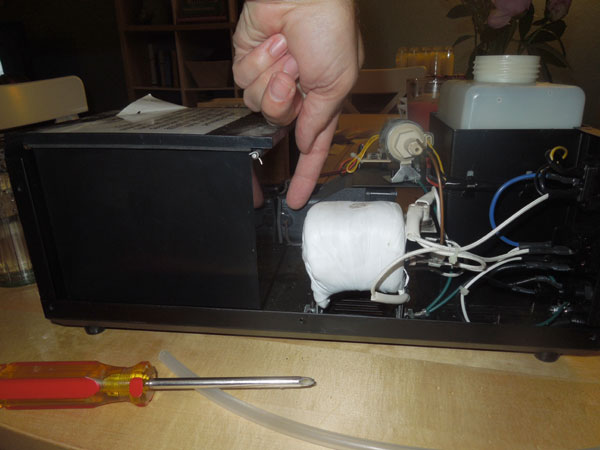

The pump pushes fluid into the heater. The mass of the heater is mostly a large aluminum heat exchange that the liquid is forced through. The heater is wrapped in a long strip of white foam insulation.

http://en.wikipedia.org/wiki/File:Fogger_Insides.JPG

After the heater, the fluid exits through another thin tube, where it is blown into the large chamber at the front of the machine.

This chamber is sometimes set up to hold some ice cubes. This is the final room before exiting the fog machine.

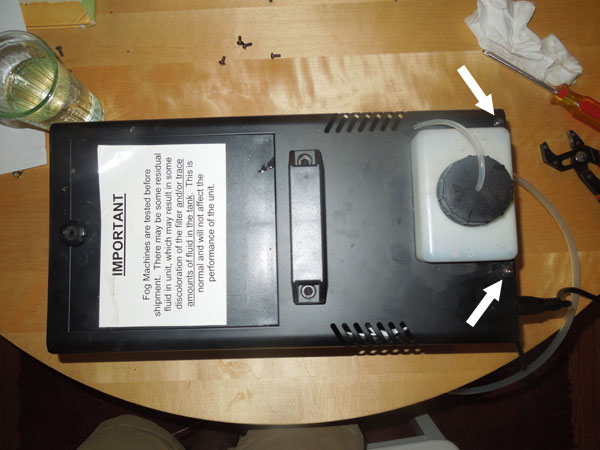

To clear a blocked machine, open it up by removing the lid.

First, unplug the machine. There are five screws on each side and two screws on top. Your machine may vary. When removing the top, you will have to pull the fluid feed tube out of the fluid reservoir.

To dislodge what is likely a sticky blockage, use a small bulb syringe to push water in, through the feed tube.

Also, loosen the bolt which holds the metal exit tube onto the pump. The bolt should drop back away from the pump and remain rattling around on the metal tube.

Gently pull the tube mouth away from the pump and push some water into the tube. The pump is probably the bottleneck of the whole system, so concentrate your efforts there. Another bottleneck is the heat-exchange, so test the flow of fluid through that area as well. Your bulb of water should be able to force out or dissolve any gummy residue inside.

There should be two tube segments now.

- The feed tube and the pump and

- the metal tube and the heater.

When you can force liquid through both of these segments, you can be confident that the blockage has been cleared.

Re-attach the metal tube to the heater and give it a test-run.

I felt safe plugging in the machine before re-affixing the cover, just make sure you get your hand out of harm's way and be careful that you aren't standing in fluid when you plug it in.

Testing the machine takes a while because the heater will have to warm back up again each time, but with luck you should have a bountiful bank of fog filling your living room on the first try.