Disneyland Costume - page 8

back to the introduction

Splash Mountain

Unlike my first two mountainous roller coasters, Splash Mountain is a water ride. Instead of making a tiny log which circles the mountain, I aimed to create a tiny log which slides down the front into a jumble of thorny bramble bushes.

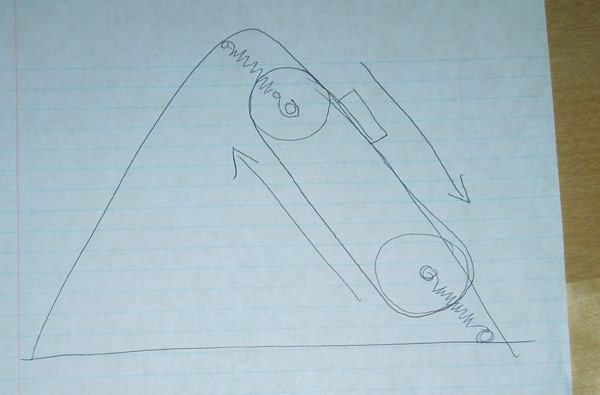

I wouldn't be satisfied with mounting a log onto a vertically rotating drum. That wouldn't look anything like a waterslide. I needed a long ramp that a plain orbit wouldn't approximate. I needed a belt drive.

A belt drive is harder to engineer than direct-drive shaft-driven turntable. I needed pulley wheels, a drive shaft and a belt. Belt drives need to be tensioned, pulling against the belts with at least as much force as they are trying to exert on the other pulleys.

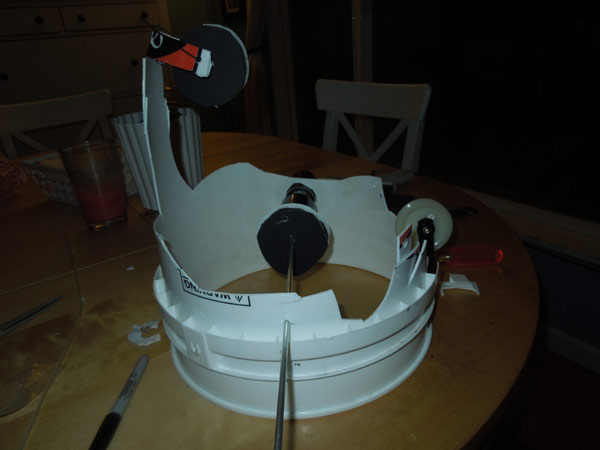

My first tactic was to make pulley wheels out of foamboard and use a thin pink rope for a belt. I mounted one of the disco ball motors at the base of the bucket. My design flair was flaring up, so I left part of the bucket intact, bending down the upper edge of the plastic bucket to make a pulley mount.

I had an idea that the resiliency of the plastic bucket would be the ideal dose of tension on the belt. It would be an elegant solution.

I had a few problems. The shafts weren't aligned well enough, the pulleys weren't well engineered and didn't have enough friction to grip the rope.

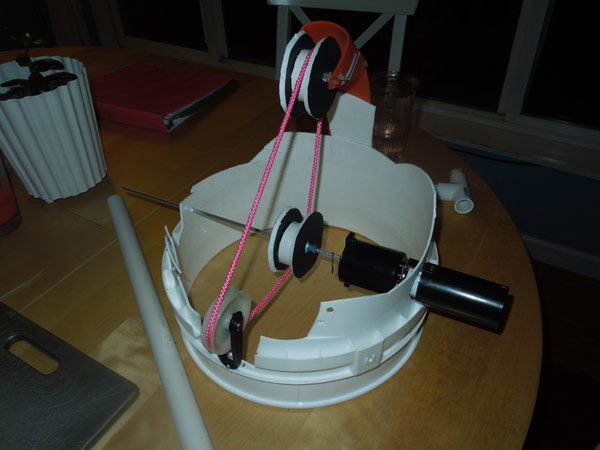

I added a third pulley. I made new pulleys out of a cross section of 1" PVC pipe.

I re-aligned the motor pulley.

I cut an old bicycle tire to make a cyndrical cover for one of the pulleys (Another option was to make a belt out of the tire).

After about three hours of tinkering, it was time to give up the bent-bucket spring idea. It didn't provide enough tension. I'd have to abandon some of this construction and start again.

Please Continue Reading Page 9 >

back to the introduction