How I Made a Mini Target Ball Out of Cement

Everyone I know is drawn to these curious round balls. I wanted my own.

By Rob Cockerham |

The first time I saw the giant red cement balls out in front of Target, I was intrigued.

Who thought of this? What was the process to make these giant concrete balls and to install them? How much do they weigh? How much do they cost? How are they anchored?

With a 24" diameter, they were the perfect size to draw in children and adults alike. I wanted something like this in my own yard!

My friend Donna had a different reaction, she wanted to know what it would be like to hold one of these cement balls in the palm of her hand.

I thought I could totally make that happen.

Now that I have a 3D printer, a world of projects has opened up.

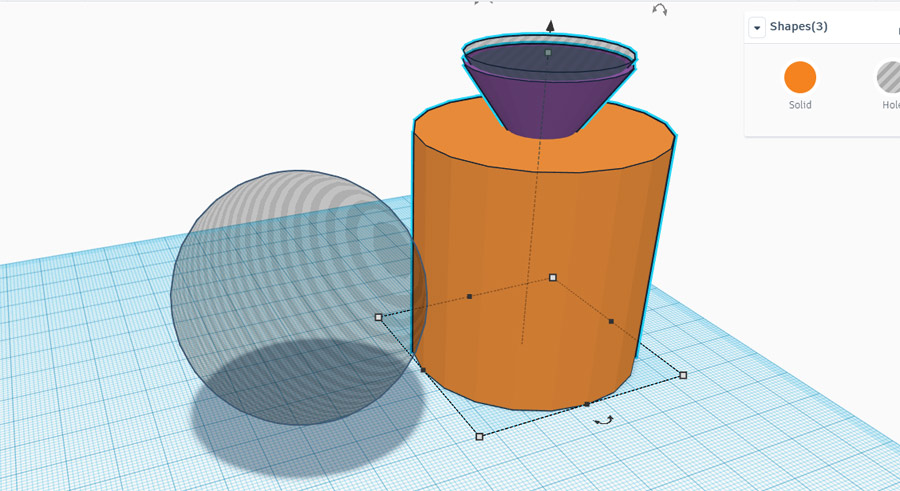

Not only can I create objects out of plastic, I can make mock-ups, models, tools, clamps, armatures and molds. To make a concrete ball, I needed a simple mold. I loaded tinkercad and dragged a handful of simple shapes onto the workspace. A cylinder would be strong enough to hold the shape, and when positioned around and grouped with a "negative" ball shape inside, I'd have the easiest ball mold ever.

I added the shell of an inverted cone to the top (shown in purple in the image above), to act as a funnel for the wet cement.

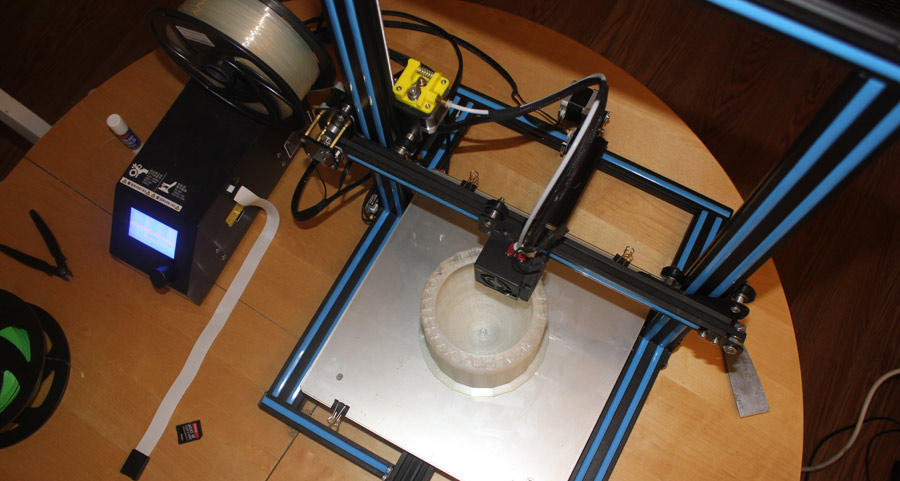

After running the 3D file through the model slicer, I had a chunk of G-Code that my printer could handle. After a short warm-up, the printer sprang to life.

It was almost the shape of a vase.

A vase which held a perfect sphere of water.

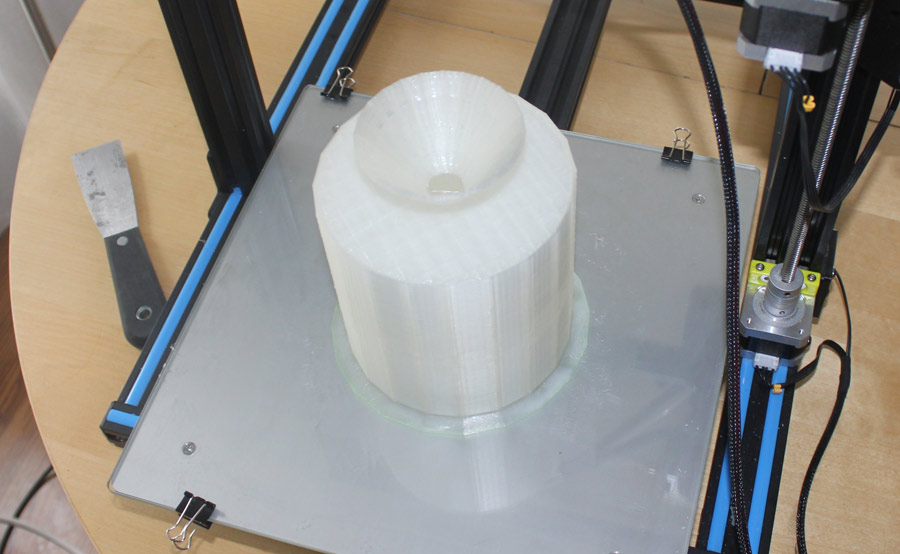

This 10" cylinder slowly took shape on the platform of the 3D printer. After 15 hours, I had a sturdy mold, ready for testing with some genuine concrete.

The only problem was, I'd have to destroy the mold to get the ball out.

The funnel was big enough, but the aperture was only as big as my finger. I decided to use cement instead of concrete. Cement is smoother, easier to ram into a tight spot.

It didn't take much. A tiny batch of wet cement flowed slowly into my mold. I could see that it was filling an internal void, but I couldn't actually see the shape.

A day later, the cement looked dry and it was time to crack open the cylindrical shell.

With the help of a utility knife, I sliced the cylinder in half, revealing half of a cement ball! Success! With another hour of heat and prying, I was able to pry the ball out of the mold.

It looked awesome!

Actually, it was a little.. uh, non-spherical. The result was a somewhat oblate spheroid. I don't know if you can see it in these photos.

It also showed the 200 facets created when I used a low-res sphere model in Tinkercad.

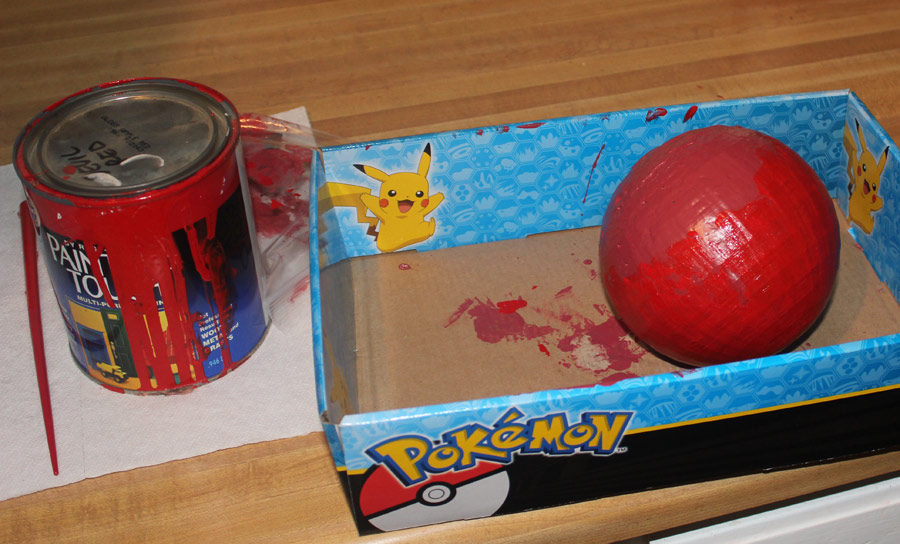

Painted red, it looked magnificent! It was dense, of course, so this little ball weighs about eight pounds.

Now I just have to finish building my 1/6th scale Target store in the backyard, and my life will be complete!