I 3D printed some Easter Eggs! With money inside!

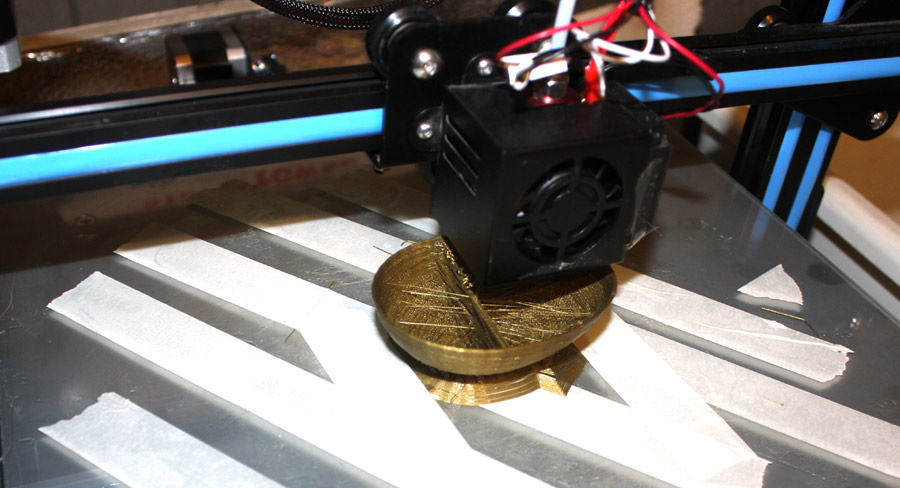

3D printing is a slow process. A hot nozzle heats up and squirts molten hot plastic in a carefully determined pattern to form a three dimentional object. It's like using a hot glue gun to squirt out an entire sculpture. It takes time.

Not long after I first received my printer, I realized that I could pause printing momentarily and fill up a hollow object. I made salt and pepper shakers this way, filling up a clear shaker with no filling door or portal.

This Easter, I decided to try making an egg, sealed shut with money trapped inside!

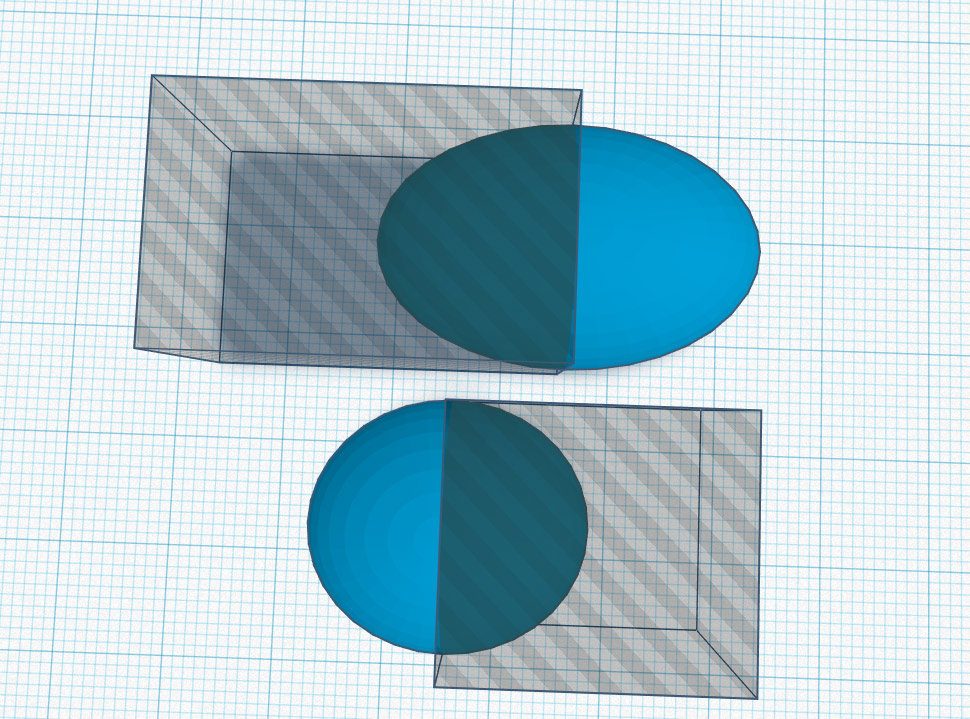

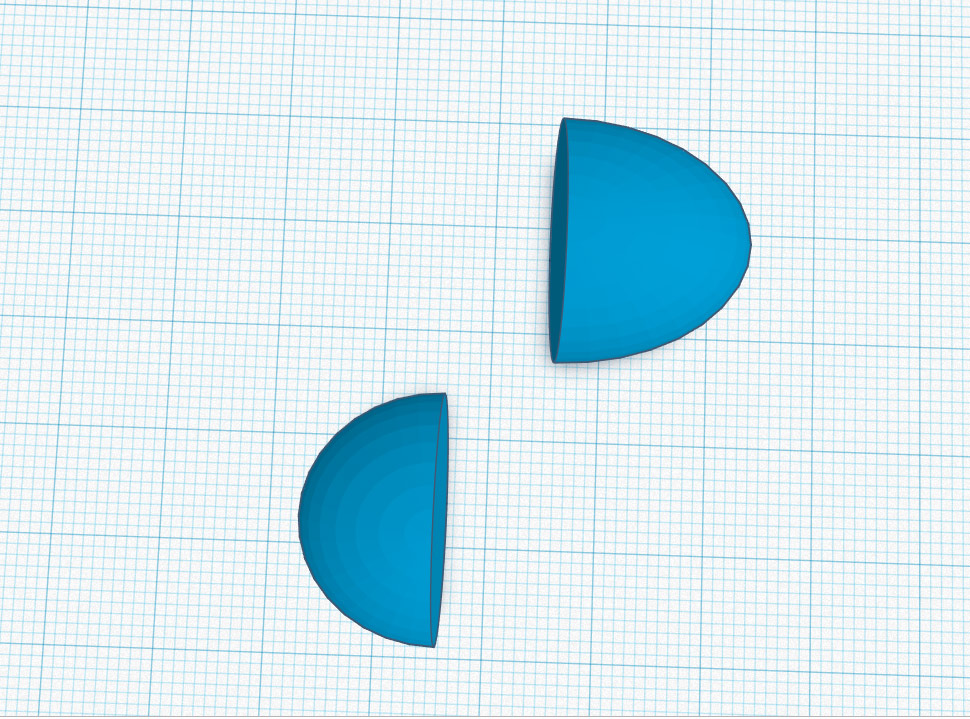

The first step was to design an egg shape. I use TinkerCAD to design simple shapes like this hollow egg. An egg has a mostly round side and one oblated side, so I made the two halves seperately.

And then I stuck them together.

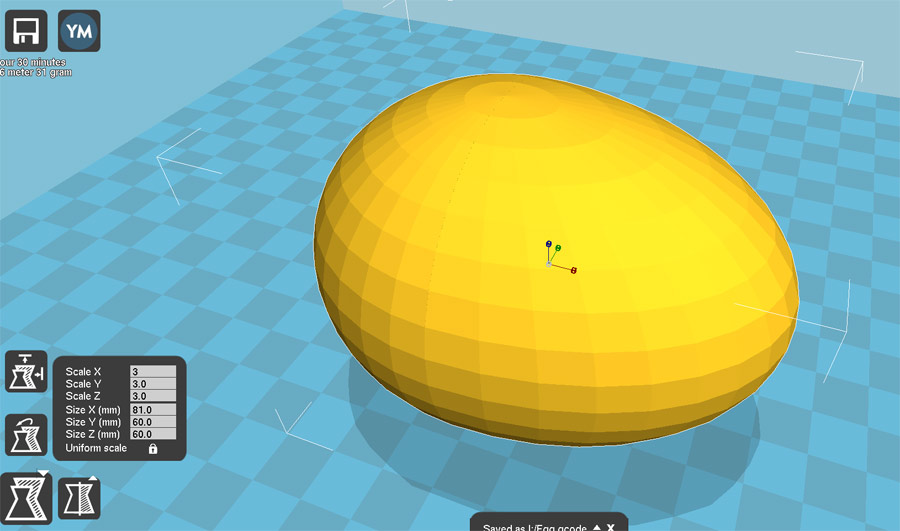

In the 3D printing "slicing" software, there is a setting to print "hollow", "solid", or any % of filled in between. It is called the "infill" setting.

Hollow objects are weaker than solid objects, but with just a few walls inside of an object, you can make a structure incredibly strong. My eggs would be hollow.

The slicing software is pretty good at guessing how long a print will take, and an egg this size looked like it was going to take about an hour to print. I set up the printer with some amazing gold-tone metallic filament, and started printing an egg.

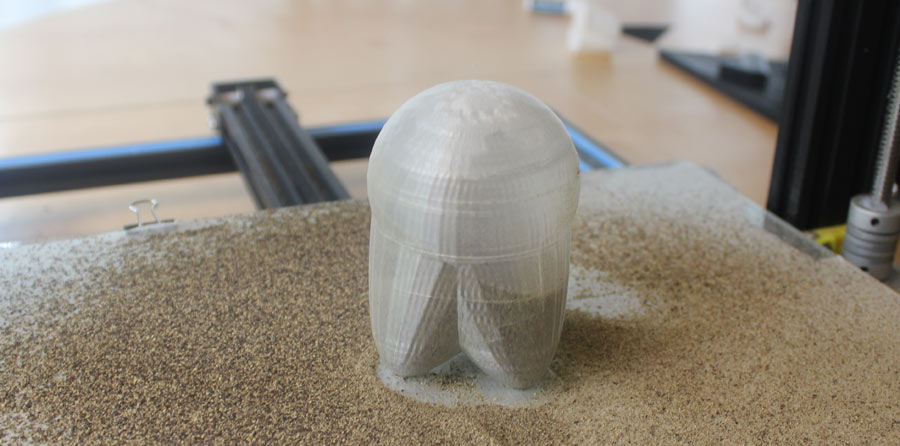

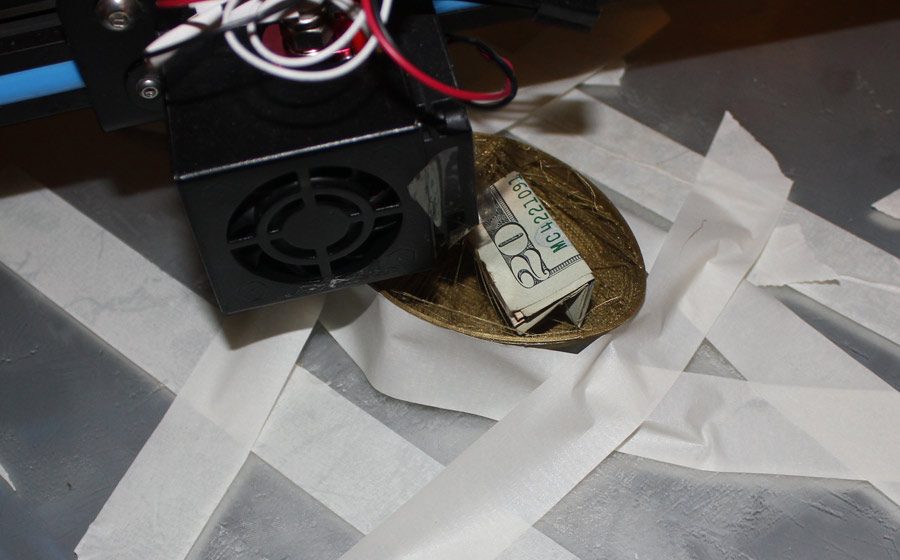

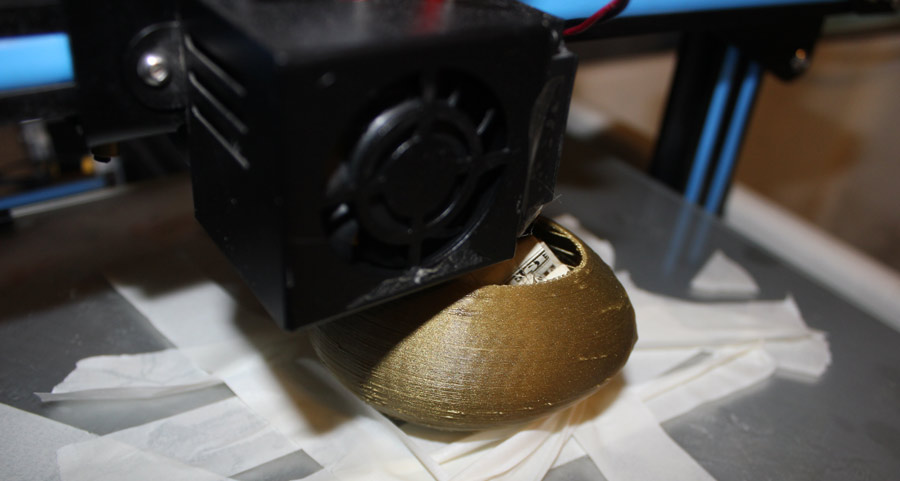

At about the halfway point, I slipped a bill into the shell. I didn't even pause the print, because it's pretty easy to plop a bill down into a little eggshell, even with a hot print head zipping around the object.

A few minutes later, the egg was almost complete!

Kids, none of the eggs really contain a $20 bill. That was just for the camera. Your eggs have $1 bills.

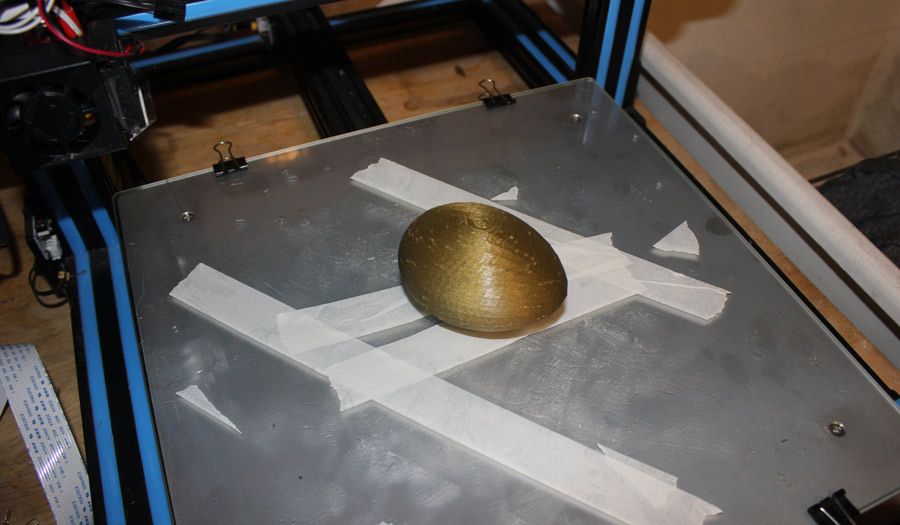

In about 75 minutes, the first egg was done! It looked shiny and beautiful! It was also about 50% larger than a regular chicken egg, so it was pretty impressive.

A few hours later, I had a few eggs done! I ran out of bills for the third egg, so I crammed a bunch of coins into the third one.

It is much better, because you can hear the coins rattling around inside the egg.

I can't wait to hide these in the grass! I wonder if the kids will prefer to keep them, or to smash them up and pilfer the treat inside?